Vacuum System

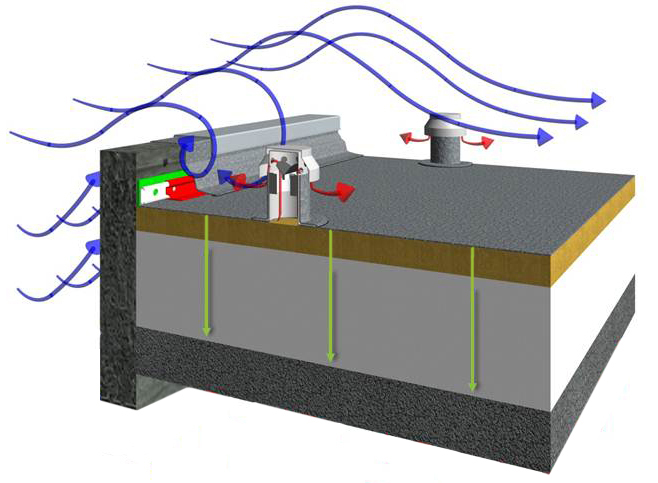

The wind forces create a vacuum effect that sucks the membrane firmly onto the roof structure. The windier it is, the better the system works.

Protan Vacuum System is unique because it only requires mechanical fasteners around the perimeter areas, not the central roof area. That makes it ideal for refurbishment projects.

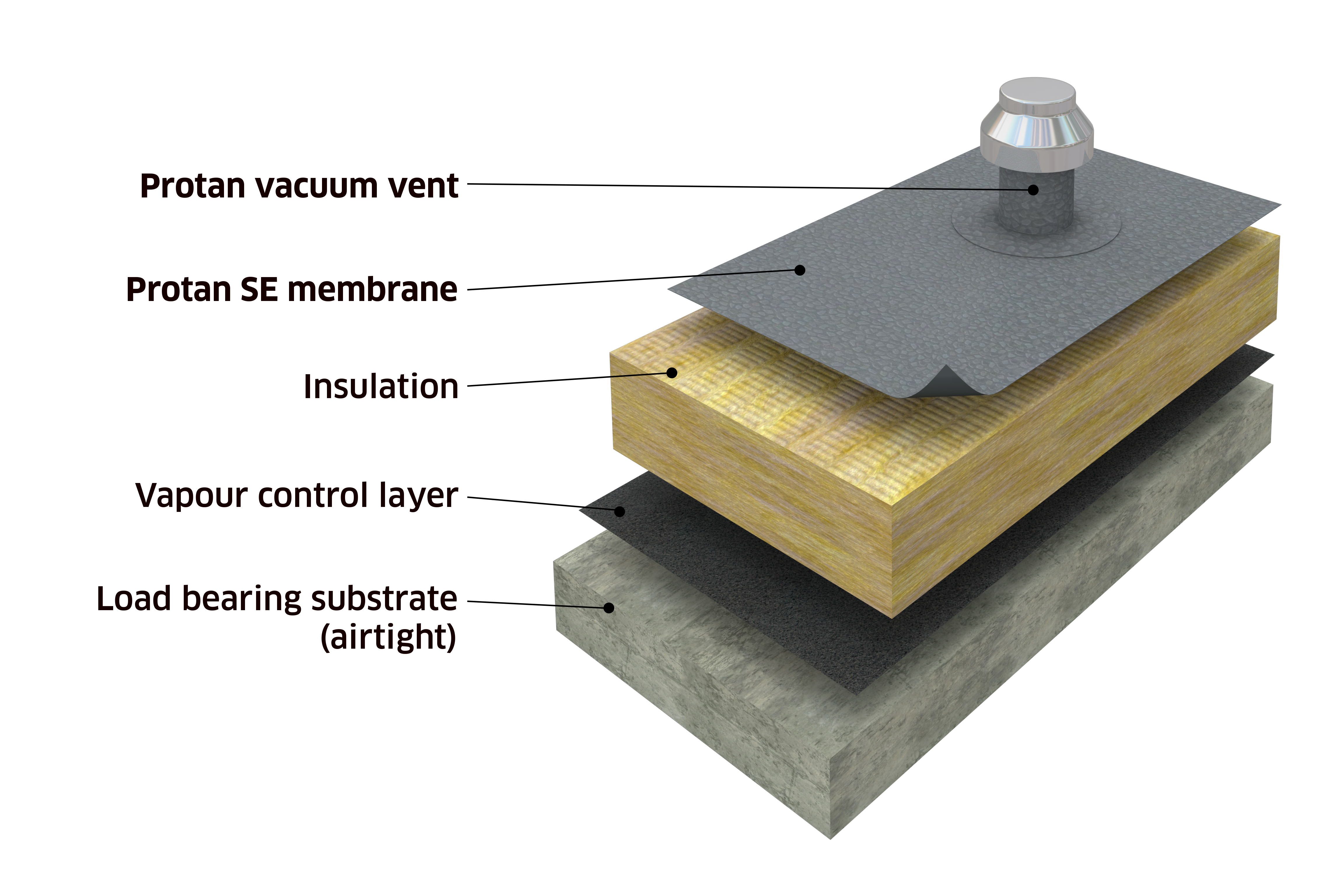

A Protan approved, torch-on, bituminous vapour control layer is installed over the air-tight structural roof deck, followed by Protan approved insulation and Protan SE or EX single-ply membrane.

Ideally, the insulation is loose-laid mineral wool boards, although other types of insulation can be installed in combination with mineral wool. The location and number of Protan vacuum vents is calculated by Protan’s Technical Services Department.

As the wind blows, the air in the space between the Protan membrane and the air-tight structural roof deck is sucked out of the system through the Protan vacuum vents’ one-way air valves. The vacuum that is created holds the Protan membrane in place, so mechanical restraint is only required around the roof perimeter and penetrations.